Linear motor drive technology, as a new type of feed transmission developed in recent years, has been attached importance in the global machine tool industry by virtue of its advantages, and set off a wave of linear motor in Europe and other industrial developed regions.

Linear motor can directly produce continuous single direction or back and forth linear mechanical motion, without intermediate mechanical transmission conversion device, linear motor drive technology has been gradually mature since its birth and development, at the same time, linear motor as a new driving technology, With the unique advantages of high precision, less wear, fast response, low noise, high operating efficiency and small volume, linear motor has become the ideal transmission mode of all kinds of ultra-high speed and precision machine tools. In laser cutting, engraving, marking, boring line, precision CNC machine tools, precision testing equipment, industrial automation, logistics and transportation system has a wide range of applications.

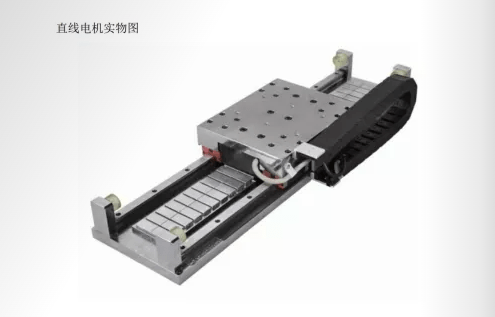

Linear motor drive characteristics

In the machine tool feed system, the biggest difference between the linear motor drive and the original rotary motor drive is to cancel all the mechanical intermediate transmission link from the motor to the workbench (drag plate), and shorten the length of the machine tool feed drive chain to zero. This mode of transmission is called zero transmission. It is because of this zero transmission mode that the original rotary motor drive mode cannot achieve the performance index and some advantages.

Special driver for Vector linear motor

As a technology leader in the field of motion control in China, Vector not only customizes all kinds of special servo drives for various industries. Moreover, we have developed the VC800 high-performance linear motor servo driver by combining 18 years of experience and innovative technology in motion control industry with keen industrial technology and wind direction perception. By integrating the latest servo control technology, we can realize the high precision control of linear motor.

Vector VC800 linear motor driver has the following features:

Compatible with standard incremental ABZ encoder, optional HALLU HALLV HALLW.

Incremental ABZ encoder directly uses the photoelectric conversion principle to output three groups of square wave pulses A, B and Z phases. The phase difference between group A and group B is 90. Thus, the direction of rotation can be easily judged, and the Z phase is a pulse per revolution for reference point positioning. Principle structure is simple, the average life of the machine can be in tens of thousands of hours, strong anti-interference ability, high reliability.

It can be configured as automatic phase search on power-on. The actuator phase can also be accurately obtained under the condition of load disturbance and one-way blocked rotation.

The matching motor is simple, with automatic identification of stator winding parameters, automatic identification of actuator quality, estimation of magnetic pole distance and automatic setting of current ring bandwidth. VECObserver software can quickly match linear motors.

Support dynamic braking function, in abnormal circumstances can make the motor fast braking, prevent the speed.

The location of the maximum support 4 MHZ command input, after 4 times AB pulse frequency can be up to 16 MHZ.

Support position correction function. After correction, the magnetic encoder can achieve the maximum positioning accuracy of ±1μm.

Respond quickly. The fastest current loop control cycle is 80KHz, and the fastest speed loop control cycle is 40KHz.

Post time: Apr-04-2023