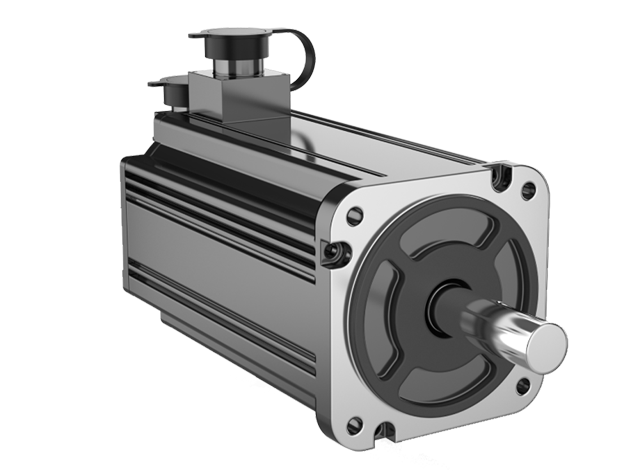

As a key component in the field of automation, servo drives have a series of unique characteristics, which promote the rapid development of industrial automation. This article will delve into the characteristics of servo drives and explain how they can play a key role in automation systems.

1. High precision and high performance

The main characteristic of servo drive is high precision and high performance. They enable very precise position and speed control, which is critical for applications that require high precision motion, such as CNC machine tools, printing equipment, and robots. This high performance makes the production process more reliable and efficient.

2. High reliability and stability

Servo drivers usually adopt advanced control algorithms, which can quickly respond to external disturbances and have high anti-interference. This high reliability and stability enables servo drives to perform well in industrial environments, maintaining superior performance even under harsh conditions.

3. Flexibility and programmability

Servo drives are usually highly flexible and can be easily adapted to different application requirements. They are usually programmable, allowing users to customize Settings according to specific application requirements. This programmability makes servo drives suitable for a variety of different types of mechanical and automation systems.

4. Real-time feedback and closed-loop control

Servo drivers usually use a closed-loop control system with real-time feedback mechanism to correct errors. This means that they can constantly adjust the output as they run to ensure that the desired position and speed are at a predetermined value. This real-time feedback mechanism is critical for applications that require high accuracy and stability.

5. Efficient energy management

Modern servo drives also have excellent energy management features. They are able to reduce power consumption when needed, thus reducing energy waste. This not only benefits the environment, but also helps reduce operating costs.

6. Multiple communication interfaces

Servo drives typically have multiple communication interfaces that allow them to be seamlessly integrated with other automation devices and control systems. This ability to interconnect makes it a key component in automated systems.

7. Long life and low maintenance costs

Servo drives are often carefully designed to ensure long-term reliability. They usually have a long life, reducing maintenance costs. This is important for industrial applications where reducing downtime is critical.

8. Various sizes and power ranges

The servo drive market offers products in various sizes and power ranges to suit the needs of different applications. This diversity allows servo drives to be found in a wide range of industrial and mechanical applications.

In general, the characteristics of servo drives make them a core component in the field of industrial automation and mechanical control. High precision, high performance, programmability and efficient energy management make servo drives play an indispensable role in the production process, driving continuous innovation and progress in the field of automation. Whether in manufacturing, medical devices or aerospace, servo drives play a key role in a variety of applications, leading the drive for the automation revolution.

Post time: Nov-02-2023